Servopulser: Dynamic and Fatigue Testing Machine

Servopulser - Dynamic and Fatigue Testing Machine is a machine for determining material properties under dynamic stress.

Shimadzu supplies a wide range of servopulser fatigue testing machines with different capacities. Models are available with electromagnetic, ultrasonic or hydraulic loading systems depending on the load and frequency achieved.

Servopulser - Dynamic and Fatigue Testing Machine

- Compact design machines capable of reaching loads up to 200 kN

- Variable frequencies depending on system configuration

- 4830 series controller for fully digital control: automatic tuning of control parameters and sine waveform distortion correction

Fatigue machine design

- The Servopulser range of fatigue machines enables dynamic and cyclic, fatigue testing.

- Variable stroke and frequency according to load, stroke and material achieved

- Software modules for KIC, JIC, standard sine wave or even static tests

Standard fatigue system configuration includes:

- A main test unit consisting of a machine frame with specimen clamping

- A 4830 controller which controls the machine and sets the test parameters either in software or on the test controller panel

- A set of valves, hoses and actuators to allow precise control of stroke, frequency and amplitude shape

a hydraulic power pack that generates the energy required to perform the tests

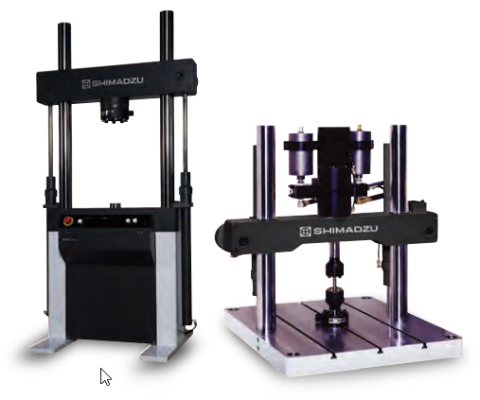

SERVOPULSER Fatigue Machine | EHF-E Series

EHF-E | Electric-Hydraulic Fatigue Testing Machine

- The Servopulser EHF-E with a bottom-mounted actuator is a fatigue machine available in frame capacities up to 50 kN, 100 kN and 200 kN.

- Shimadzu Servopulser is a complete dynamic fatigue testing system with fully electro-hydraulic servo-control and high-speed loading and data acquisition. As a result, high load accuracy of +/- 0.5% is achieved.

- The Servopulser fatigue machines evaluate e.g. dynamic springing, damping factor, fracture mechanics of KIC and JIC etc., as well as the behavior at maximum load, max. frequency 500 Hz, which is suitable for e.g. rubber and plastic testing.

- The fatigue testing machine is used for toughness (fatigue) testing or static testing in component safety assessment.

- Optional software modules guide the user in the full use of the test system.

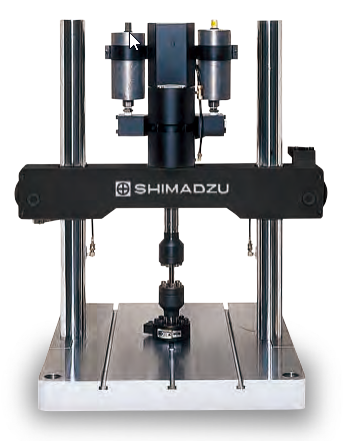

SERVOPULSER Fatigue Machine | EHF-U Series

EHF-U | Electric-Hydraulic Fatigue Testing Machine for the extra large components and parts

- The Servopulser EHF-U series with a top-mounted actuator is a test machine manufactured in the same capacities as the previous EHF-E model. However, the difference is in the machine design. The large test area allows large samples to be tested and allows the connection of various test fixtures and controlled atmosphere chambers.

- The highly rigid frame prevents unwanted deformation of the sample and avoids unwanted loss of hydraulic energy with low frame compliance.

- The testing machine incorporates a crossbar feed system that can be operated with one hand, which will be appreciated by anyone performing complex tests.

- Dynamic testing machines are available in both an extended version and with an extra large table, e.g. 2000 mm.

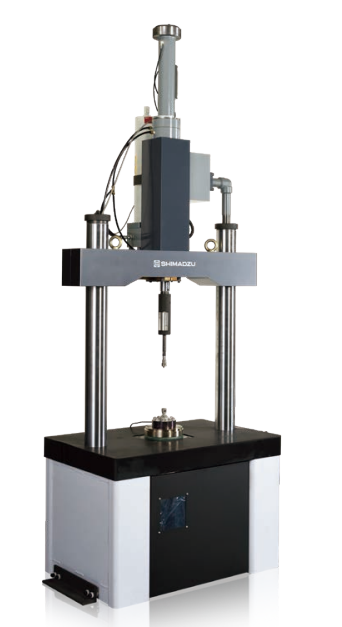

SERVOPULSER Fatigue Machine | EHF-L Series

EHF-L | Fully Digital Servo-Hydraulic Testing Machine

- The Servopulser EHF-L with a top-mounted actuator is a revolutionary fully digital servo-hydraulic dynamic load testing machine opening up new possibilities for material testing of fatigue and fracture characteristics. The EHF-L series excels in many aspects ranging from accuracy, reliability and versatility to full digital expandability thanks to a fully digital control system incorporating the latest technology.

- The test machines in this series are available in 5 kN, 10 kN and 20 kN capacities.

- Thanks to the latest technology, load accuracy of +/- 0.5% is achieved even here.

SERVOPULSER High-Speed Testing Machine | HITS-X Series

HITS-X | High-Speed Impact Testing Machine

- The Servopulser HITS-X test machine is used for specialised tests where high test speeds of up to 20 m/s are required. The stroke of this high speed load testing machine is up to 300 mm.

- The principle of the testing machine is based on the energy stored in the hydraulic fluid, which is released at high speed and then applied to the specimen to be loaded via the clamping fixtures.

- The HITS-PX testing machine is then equipped with accessories for testing according to ISO 6603-2:2000 and ASTM D 3763-06.

- The operation and data logging of the entire system is handled by the familiar and user-friendly Trapezium test software in the HITS version, as well as the control electronics of the 4870 series with a sampling frequency of 10 kHz.

- Of course, it is possible to use and test samples in chambers and atmospheres.