Texturometer

Shimadzu Tensile Tester - Texturometer, EZ Series, SX and LX

Specifications of the tensile tester machine - texturometer

One of the main purposes of the development of this testing machine was to be able to measure texture - the texturometer.

In the development of this model of testing machine, emphasis was placed on lightness and compactness - the design of the testing machine allows access to the test area from all sides, and therefore simple as well as complex fixtures can be inserted and easily handled in minimal space.

Another parameter is the ease of operation - where the tensile testing machine is suitable for placement on a table either in the laboratory, near the production line or as an additional testing machine in the test room.

At first glance, an inconspicuous but very useful helper is the control panel. The adjustable control panel allows you to read values, control the test machine or run tests. All of this is possible without connecting a computer with Trapezium software, as the machine has its own electronics and memory to perform the set tests.

EZ Test Tensile Machine - models, use of the texturometer

Shimadzu EZ SX - small test machine with max. force 500 N and stroke 500 mm, suitable for e.g. bending tests e.g. according to EN ISO 178, for compression or tensile tests of small parts such as joints of plastic parts, welds, threads, measuring the stroke of buttons in electronic devices, from food e.g. sticks or yoghurt etc.

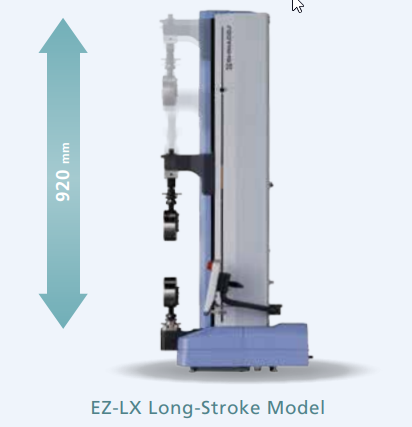

Shimadzu EZ LX - testing machine with max. force 5000N and stroke more than 900 mm, suitable for e.g. tensile tests according to EN ISO 527 and others, for tests of components, textiles, fibres, polymer films, but also e.g. for measuring the stiffness of foodstuffs, vegetables for further processing etc.

Shimadzu EZ LX HS - the testing machine is identical in size to the previous one, but its capacity is limited to 2000 N, but its maximum testing speed is increased to 2000 mm/min.

Texturometer

For use in the food and pharmaceutical industry, the TEXTURE software module has been developed, which allows to measure and evaluate (predefined results), in addition to standard quantities such as Fmax, requirements such as:

Food industry (Texture)

- Stress, force required for bite

- Food quality for cooking

- Peeling resistance

- Toughness and brittleness of food

- Crispiness

- Breaking work, tenderness

- Gumminess and chewiness

Pharmaceutical industry (QC Test)

- Tablet hardness

- The force required to break a tablet - powder

- Squeezing the liquid out of the syringe

- Strength of the packaging material

- Force required to push out of the packaging

- Needle puncture

- Measurement of the quality of medical devices (needles, condoms, sutures)

Other industries (QA, QC Tests)

- Weld strength

- Rubber Industry

- Plastic Industry

- Electornics industry

- Tissue papers

- Thin Filim / Packaging

- Strength of gypsum, binders and similar powder materials

- Bending strength of the sample (possibility of connecting a deflection sensor)

- E-module tensile strength (possibility to connect a tensile tester)

- More..

Features of the test machines, EZ test texturometer

- Like the other model series, the machines reach class 0.5 (1) from 0.2% up to the full force gauge range

- Measures crossbar displacement to within 0.1% of the displayed value

- Quiet and stable test machine - thanks to high quality ball screw and linear guide

- Shimadzu manufactures and supplies a variety of pneumatic and mechanical clamps to cover a wide range of testing applications.

- CE, RoHS and other requirements of standards and regulations are commonplace

- Force and position matching for automatic return of the cross member is done manually or automatically.

- Loading speed is guaranteed at any test force.

- The TRAPEZIUM X control software allows for two-way communication and is so intuitive that personnel can operate it reliably within minutes, etc.

- The tensile test results are saved automatically and can also be sent automatically to an assigned address or email.

- Running the test from the control panel is a matter of course and a great advantage.

- The Trapezium X software allows both multiple curve display and report including report templates.

- Custom waveforms, cyclic loading, specimen data, custom calculations - e.g. calculation of bending angle (connection of a digital protractor is a matter of course) - can then be defined in the software.

- Other accessories - strain gauge, video strain gauge, chamber, etc. - depend only on the user.