Video-Extensometer (not only) for tensile tests

The DIC video extensometer serves as a sensor - a replacement for a mechanical extensometer. The video extensometer usually consists of one camera with lens and software. The software of the video-extensometer forms the most important part of the system, because in basic mode it allows to measure the distance between two selected points and sends this value, either in absolute or proportional form, to the testing machine.

Video-Extensometer description

Video-Extensometer, in practice, it is a simple graphical environment with a lot of mathematics behind it. The software can be run automatically or manually. Importantly, the software can track an irregular cluster of pixels in a selected area and trace (correlate) that area to the next image. If two (or more) areas are created in this way and the distance between them is determined, then we have the basis for the DIC video extensometer, which is currently very popular.

Everything else is "just" mathematics that allows to calculate over-shaping, shearing or deformation velocities and accelerations.

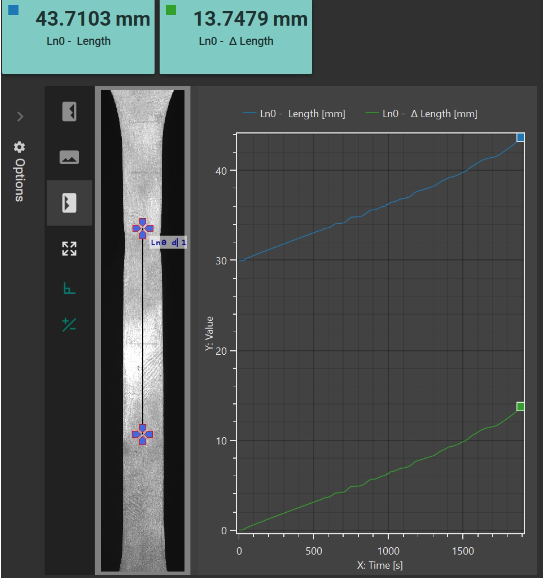

Virtual DIC video-extensometer - sample just before fracture

Video-extensometer | Applications, multiple cameras

Because it is a non-contact measurement, the video-extensometer is particularly suitable for measuring non-standardized samples or solids or for very demanding materials such as thin films or fibres, concrete wires, aerospace components, biomaterials, etc.

However, modern technology also allows measurements with multiple cameras, either by image linking (extending the field of view with the same resolution), image detail (similar to TRViewX), or stereo or 3D DIC measurements.

A calibration plate adapted to the model is then used as a calibration tool.

Advantages of the video extensometer

- Versatility of use - since it is a non-contact strain measurement, it is possible to measure both composites and standard materials in one instrument, and both widely used in the automotive industry - steel and plastic or e.g. wood, biomaterials etc.

- Safety - the video strain gauge is positioned outside the test area and is therefore safe for testing, for example, seat belts, three-wire plastics or rubber samples; it can therefore measure the tensile strength up to the failure of the sample.

- Marking-free - the DIC video extensometer "grabs" onto a natural surface - if the contrast is sufficient

- Post-processing and video recording - from the stored video, e.g. unique samples can be recalculated and evaluated

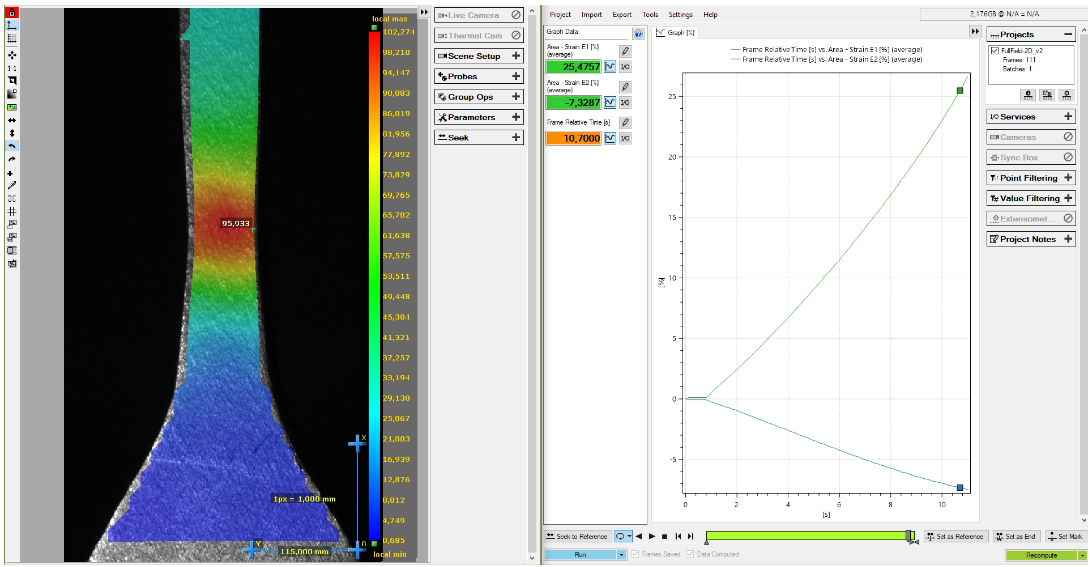

- Transform maps - the most typical function of the DIC video extensometer

- Upgradable - the simple instrument can be upgraded with additional cameras, high-speed cameras or software modules to enable additional functions and evaluation as required

DIC video extensometer left: deformation field, right: displays and sample extension/contraction

Video-Extensometer Types

DIC 200

- Measurement accuracy - Accuracy class 1, < 1%

- Mpix - 2 / 4 / 5 / 9 / 12 Mpix

- Number of cameras - 1

- Interface - USB / Ethernet / camera linc

- Height of field of view - 200 mm

DIC 400

- Measurement accuracy - Accuracy class 1, < 1%

- Mpix - 2 / 4 / 5 / 9 / 12 Mpix

- Number of cameras - 2

- Interface - USB / Ethernet / camera linc

- Height of field of view - 400 mm

DIC 600

- Measurement accuracy - Accuracy class 1, < 1%

- Mpix - 2 / 4 / 5 / 9 / 12 Mpix

- Number of cameras - 2

- Interface - USB / Ethernet / camera linc

- Height of field of view - 600 mm

Video Non-Contact Extensometer - TRViewX

TRViewX is a non-contact extensometer that offers high-measurement accuracy, is capable of measuring width changes, and is applicable to a wide variety of materials testing applications. In particular, due to the non-contact design, TRViewX is perfect for measuring films, foils, and other thin or narrow materials without affecting the specimen during testing. Furthermore, TRViewX can be used to measure displacements during atmosphere-controlled testing in a thermostatic chamber.

TRViewX | Features and Specs

Features of TRViewX

- High-Accuracy Elongation Measurements

Absolute accuracy ±1.5 μm, relative accuracy ±0.5% at room temperature

(ISO 9513 Class 0.5 and JIS B7741 Class 0.5)

Absolute accuracy ±3 μm, relative accuracy ±1.0% for in-chamber testing

(ISO 9513 Class 1 and JIS B7741 Class 1) - Width Measurement Functionality

Absolute accuracy ±2 μm, relative accuracy ±0.5% at room temperature

(ISO 9513 Class 1 and JIS B7741 Class 1)

Enables Lankford (r) value

Specification of TRViewX

- Type: Optical non-contact, standard line mark tracking format

- Guage length: Any length within camera field of view

- Camera filed of view: 55 to 800 mm

- Measurement accuracy: The larger of ±1.5 µm or ±1.5 % of indicated value (for camera field of view 240 mm or less and constant temperature measurement)